Jenvin Modular AHU

TICA modular AHU includes four series: Jingling, Jenvin, Jingzhi, and Jingxin. Jingling supports various combinations of function sections to meet different demands, and is applicable to process sites such as electronics, hospitals, pharmaceutical, food, tobacco, automotive coating, precision optical machinery, and textile, as well as comfort sites such as metros, exhibition centers, airports, office buildings, hotels, restaurants, and shopping malls.

Advantage

Technical Parameter

-

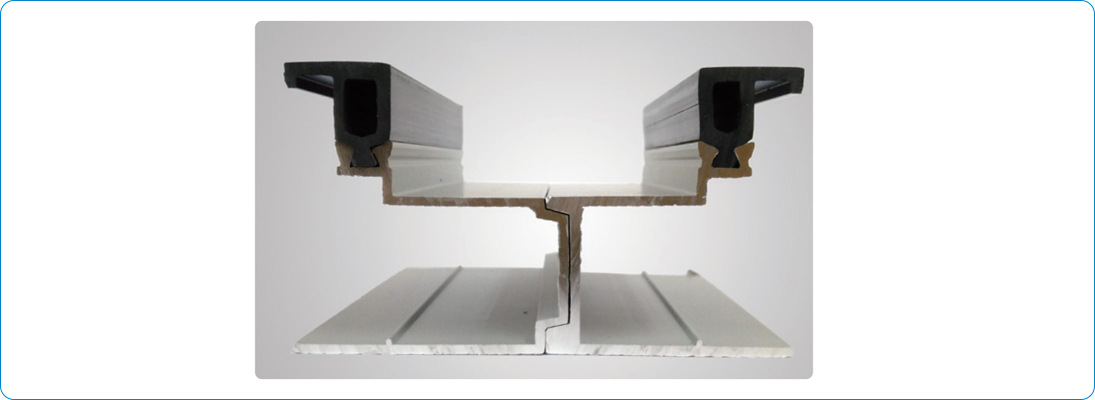

Patented Labyrinth Box

-

EN and US Standard Selection Software

-

Patent Access Door Designed Using Aviation Technologies

-

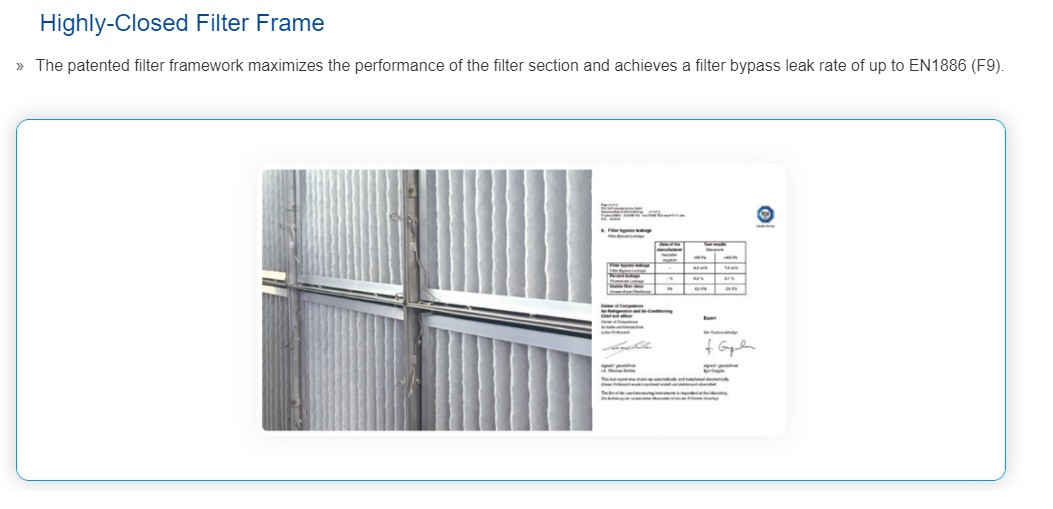

Highly-Closed Filter Frame

-

Professional Detail Design

Joints of case plates adopt aluminum alloy profile with a concave groove and a convex groove, and are secured with bolds and nuts, to form a labyrinth sealing structure. This ensures high mechanical strength (EN1886 D1) and substantially reduces the leakage rate (EN1886 L1). Besides, the labyrinth structure allows for easy disassembly and maintenance.

» The built-in templates and unit model database are designed based on the rich experience of TICA in the modular AHU field, and can meet requirements for different case dimensions in various scenarios. Users can directly use an existing module to achieve fast selection. Professional selection of core components such as the heat exchanger, fan and motor. The models with the highest cost performance will be automatically matched. Heat exchanger selection complies with US standard. The model selection results can be intuitively checked with a complete set of reports provided, including the technical parameter detail list of each functional section of the unit, the coil model selection detail list, enthalpy/humidity chart, operating conditions, and unit size diagram. The report authenticity complies with EN standard.

» The access door adopts overall foam molding to achieve high strength and small deformation and double knife edge sealing to avoid leakage; it is also provided with a special safe pressure relief device to ensure safety performance of the access door.

Business Contact

If you have any questions about TICA products, please contact us.

Leave us a message

[wpforms id="396"]